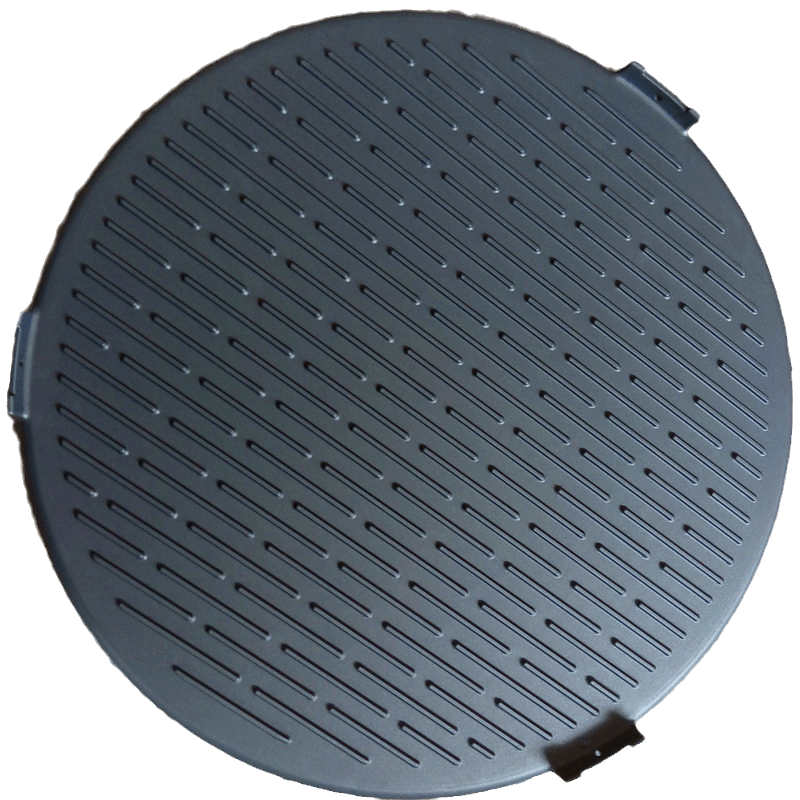

An aluminium die-cast baking tray is a type of baking tray made from aluminum that is cast using a die-casting process. Die-casting is a manufacturing process in which molten metal is injected into a mold or die to create a desired shape. Aluminium is a popular material for baking trays because it is lightweight, durable, and a good conductor of heat, which helps to evenly bake foods. Die-cast aluminium baking trays may be coated with a non-stick material to make them easier to clean and to prevent foods from sticking to the surface. They are often used for baking cookies, bread, and other baked goods.

There are several advantages to using a die-cast aluminium baking tray:

- Lightweight: Aluminium is a lightweight material, making it easy to handle and transport. This can be especially useful if you need to move the tray in and out of the oven frequently.

- Durability: Aluminium is a strong and durable material that can withstand high temperatures and is resistant to warping.

- Heat conductivity: Aluminium is a good conductor of heat, which helps to evenly bake foods.

- Non-stick properties: Many die-cast aluminium baking trays are coated with a non-stick material, which makes them easy to clean and prevents foods from sticking to the surface.

- Versatility: Die-cast aluminium baking trays are suitable for a variety of baking tasks, including roasting, broiling, and grilling.

- Cost-effective: Aluminium is generally less expensive than other materials, making die-cast aluminium baking trays a cost-effective choice.

There are several surface treatment options for aluminium die-cast baking trays:

- Non-stick coatings: These coatings, such as Teflon, are applied to the surface of the baking tray to make it easier to clean and to prevent foods from sticking to the surface. Non-stick coatings can be applied either by spraying or dipping the tray in a non-stick solution.

- Anodizing: This process involves electrochemically treating the surface of the aluminium to create a durable, corrosion-resistant finish. Anodizing can also be used to create a variety of colors on the surface of the baking tray.

- Powder coating: This process involves applying a layer of dry, finely ground particles of pigment and resin to the surface of the aluminium. The particles are then melted and cured to create a durable, smooth finish.

- Polishing: The surface of the aluminium can be polished to create a shiny, reflective finish. This process involves buffing the surface of the metal with abrasive materials to remove imperfections and create a smooth finish.

- Etching: This process involves using chemicals to remove a thin layer of the surface of the aluminium, creating a textured finish. Etching can be used to create patterns or designs on the surface of the baking tray.